Page 125 - Industrial Cutting of Textile Materials

P. 125

112 Industrial Cutting of Textile Materials

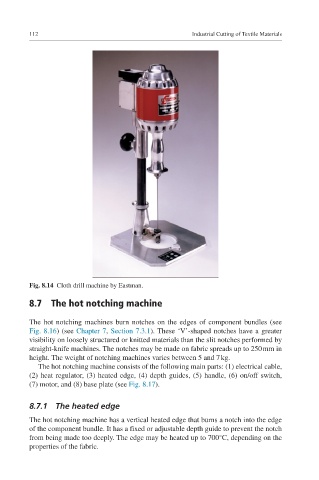

Fig. 8.14 Cloth drill machine by Eastman.

8.7 The hot notching machine

The hot notching machines burn notches on the edges of component bundles (see

Fig. 8.16) (see Chapter 7, Section 7.3.1). These ‘V’-shaped notches have a greater

visibility on loosely structured or knitted materials than the slit notches performed by

straight-knife machines. The notches may be made on fabric spreads up to 250 mm in

height. The weight of notching machines varies between 5 and 7 kg.

The hot notching machine consists of the following main parts: (1) electrical cable,

(2) heat regulator, (3) heated edge, (4) depth guides, (5) handle, (6) on/off switch,

(7) motor, and (8) base plate (see Fig. 8.17).

8.7.1 The heated edge

The hot notching machine has a vertical heated edge that burns a notch into the edge

of the component bundle. It has a fixed or adjustable depth guide to prevent the notch

from being made too deeply. The edge may be heated up to 700°C, depending on the

properties of the fabric.