Page 135 - Industrial Cutting of Textile Materials

P. 135

122 Industrial Cutting of Textile Materials

Cut multi-ply spread

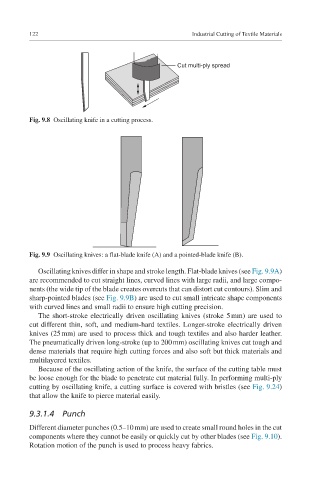

Fig. 9.8 Oscillating knife in a cutting process.

Fig. 9.9 Oscillating knives: a flat-blade knife (A) and a pointed-blade knife (B).

Oscillating knives differ in shape and stroke length. Flat-blade knives (see Fig. 9.9A)

are recommended to cut straight lines, curved lines with large radii, and large compo-

nents (the wide tip of the blade creates overcuts that can distort cut contours). Slim and

sharp-pointed blades (see Fig. 9.9B) are used to cut small intricate shape components

with curved lines and small radii to ensure high cutting precision.

The short-stroke electrically driven oscillating knives (stroke 5 mm) are used to

cut different thin, soft, and medium-hard textiles. Longer-stroke electrically driven

knives (25 mm) are used to process thick and tough textiles and also harder leather.

The pneumatically driven long-stroke (up to 200 mm) oscillating knives cut tough and

dense materials that require high cutting forces and also soft but thick materials and

multilayered textiles.

Because of the oscillating action of the knife, the surface of the cutting table must

be loose enough for the blade to penetrate cut material fully. In performing multi-ply

cutting by oscillating knife, a cutting surface is covered with bristles (see Fig. 9.24)

that allow the knife to pierce material easily.

9.3.1.4 Punch

Different diameter punches (0.5–10 mm) are used to create small round holes in the cut

components where they cannot be easily or quickly cut by other blades (see Fig. 9.10).

Rotation motion of the punch is used to process heavy fabrics.