Page 137 - Industrial Cutting of Textile Materials

P. 137

124 Industrial Cutting of Textile Materials

9.3.2 The cutting table

The cutting process is carried out on flatbed static or conveyorized tables. They are

available in different width and different length. The width of the table depends on

the processed fabric width, but the length of the table can be expanded by using more

separate table segments. Often, the cutting table may be developed depending on the

application.

9.3.2.1 Static tables

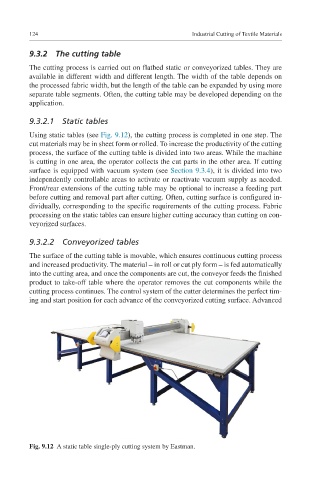

Using static tables (see Fig. 9.12), the cutting process is completed in one step. The

cut materials may be in sheet form or rolled. To increase the productivity of the cutting

process, the surface of the cutting table is divided into two areas. While the machine

is cutting in one area, the operator collects the cut parts in the other area. If cutting

surface is equipped with vacuum system (see Section 9.3.4), it is divided into two

independently controllable areas to activate or reactivate vacuum supply as needed.

Front/rear extensions of the cutting table may be optional to increase a feeding part

before cutting and removal part after cutting. Often, cutting surface is configured in-

dividually, corresponding to the specific requirements of the cutting process. Fabric

processing on the static tables can ensure higher cutting accuracy than cutting on con-

veyorized surfaces.

9.3.2.2 Conveyorized tables

The surface of the cutting table is movable, which ensures continuous cutting process

and increased productivity. The material – in roll or cut ply form – is fed automatically

into the cutting area, and once the components are cut, the conveyor feeds the finished

product to take-off table where the operator removes the cut components while the

cutting process continues. The control system of the cutter determines the perfect tim-

ing and start position for each advance of the conveyorized cutting surface. Advanced

Fig. 9.12 A static table single-ply cutting system by Eastman.