Page 270 - Industrial Cutting of Textile Materials

P. 270

Automated single-ply processing of styles from intricate pattern textiles 257

a

6

7

3

5

2

4

1

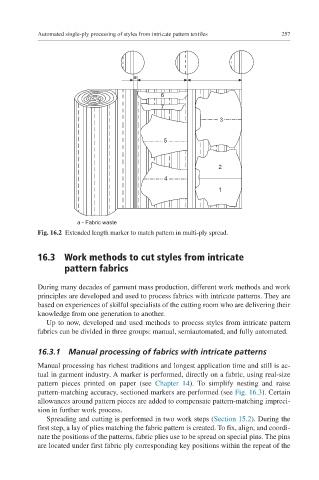

a - Fabric waste

Fig. 16.2 Extended length marker to match pattern in multi-ply spread.

16.3 Work methods to cut styles from intricate

pattern fabrics

During many decades of garment mass production, different work methods and work

principles are developed and used to process fabrics with intricate patterns. They are

based on experiences of skilful specialists of the cutting room who are delivering their

knowledge from one generation to another.

Up to now, developed and used methods to process styles from intricate pattern

fabrics can be divided in three groups: manual, semiautomated, and fully automated.

16.3.1 Manual processing of fabrics with intricate patterns

Manual processing has richest traditions and longest application time and still is ac-

tual in garment industry. A marker is performed, directly on a fabric, using real-size

pattern pieces printed on paper (see Chapter 14). To simplify nesting and raise

pattern-matching accuracy, sectioned markers are performed (see Fig. 16.3). Certain

allowances around pattern pieces are added to compensate pattern-matching impreci-

sion in further work process.

Spreading and cutting is performed in two work steps (Section 15.2). During the

first step, a lay of plies matching the fabric pattern is created. To fix, align, and coordi-

nate the positions of the patterns, fabric plies use to be spread on special pins. The pins

are located under first fabric ply corresponding key positions within the repeat of the