Page 275 - Industrial Cutting of Textile Materials

P. 275

262 Industrial Cutting of Textile Materials

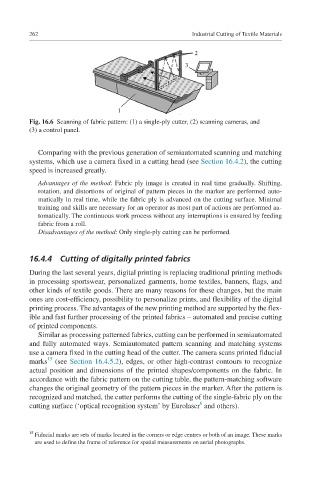

Fig. 16.6 Scanning of fabric pattern: (1) a single-ply cutter, (2) scanning cameras, and

(3) a control panel.

Comparing with the previous generation of semiautomated scanning and matching

systems, which use a camera fixed in a cutting head (see Section 16.4.2), the cutting

speed is increased greatly.

Advantages of the method: Fabric ply image is created in real time gradually. Shifting,

rotation, and distortions of original of pattern pieces in the marker are performed auto-

matically in real time, while the fabric ply is advanced on the cutting surface. Minimal

training and skills are necessary for an operator as most part of actions are performed au-

tomatically. The continuous work process without any interruptions is ensured by feeding

fabric from a roll.

Disadvantages of the method: Only single-ply cutting can be performed.

16.4.4 Cutting of digitally printed fabrics

During the last several years, digital printing is replacing traditional printing methods

in processing sportswear, personalized garments, home textiles, banners, flags, and

other kinds of textile goods. There are many reasons for these changes, but the main

ones are cost-efficiency, possibility to personalize prints, and flexibility of the digital

printing process. The advantages of the new printing method are supported by the flex-

ible and fast further processing of the printed fabrics – automated and precise cutting

of printed components.

Similar as processing patterned fabrics, cutting can be performed in semiautomated

and fully automated ways. Semiautomated pattern scanning and matching systems

use a camera fixed in the cutting head of the cutter. The camera scans printed fiducial

15

marks (see Section 16.4.5.2), edges, or other high-contrast contours to recognize

actual position and dimensions of the printed shapes/components on the fabric. In

accordance with the fabric pattern on the cutting table, the pattern-matching software

changes the original geometry of the pattern pieces in the marker. After the pattern is

recognized and matched, the cutter performs the cutting of the single-fabric ply on the

6

cutting surface (‘optical recognition system’ by Eurolaser and others).

15 Fiducial marks are sets of marks located in the corners or edge centres or both of an image. These marks

are used to define the frame of reference for spatial measurements on aerial photographs.