Page 38 - Industrial Cutting of Textile Materials

P. 38

Lay planning and marker making in textile cutting operations 25

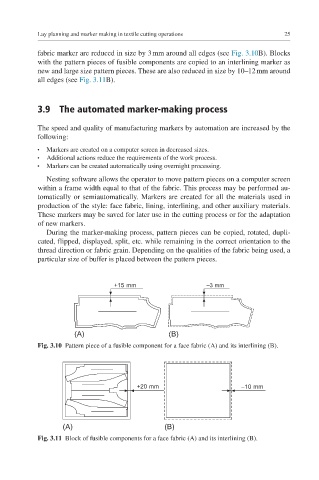

fabric marker are reduced in size by 3 mm around all edges (see Fig. 3.10B). Blocks

with the pattern pieces of fusible components are copied to an interlining marker as

new and large size pattern pieces. These are also reduced in size by 10–12 mm around

all edges (see Fig. 3.11B).

3.9 The automated marker-making process

The speed and quality of manufacturing markers by automation are increased by the

following:

Markers are created on a computer screen in decreased sizes.

●

Additional actions reduce the requirements of the work process.

●

Markers can be created automatically using overnight processing.

●

Nesting software allows the operator to move pattern pieces on a computer screen

within a frame width equal to that of the fabric. This process may be performed au-

tomatically or semiautomatically. Markers are created for all the materials used in

production of the style: face fabric, lining, interlining, and other auxiliary materials.

These markers may be saved for later use in the cutting process or for the adaptation

of new markers.

During the marker-making process, pattern pieces can be copied, rotated, dupli-

cated, flipped, displayed, split, etc. while remaining in the correct orientation to the

thread direction or fabric grain. Depending on the qualities of the fabric being used, a

particular size of buffer is placed between the pattern pieces.

+15 mm –3 mm

(A) (B)

Fig. 3.10 Pattern piece of a fusible component for a face fabric (A) and its interlining (B).

+20 mm –10 mm

(A) (B)

Fig. 3.11 Block of fusible components for a face fabric (A) and its interlining (B).