Page 149 - Industrial Wastewater Treatment, Recycling and Reuse

P. 149

Advanced Physico-chemical Methods of Treatment for Industrial Wastewaters 123

In the vortex diode, D represents the diode chamber, while H is the

chamber height. The diameters at different points at the inlet and outlet

are represented in the figure by the shaded regions and can be parameters

for specific design. As can be seen, the design can have many variations

in the size and shape of chamber and modifications that can alter the flow

pattern within the device. The flow through the device is complex, and

some studies using computational fluid dynamics have been carried out to

obtain insight into the flow pattern and its impact on the cavitation process

(Bashir et al., 2011; Kulkarni et al., 2008; Pandare and Ranade, 2013). How-

ever, as far as application of cavitation technology to wastewater is con-

cerned, the approach is largely empirical with preliminary experimental

studies required for obtaining useful data on the degradation of pollutants

and the optimization of process parameters, similarly to coagulation processes.

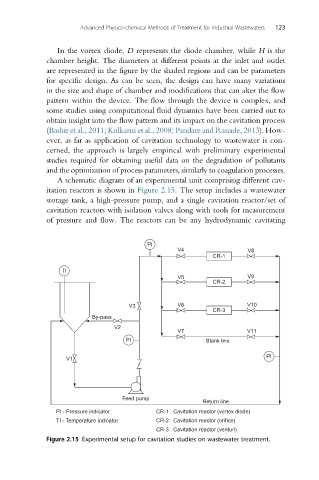

A schematic diagram of an experimental unit comprising different cav-

itation reactors is shown in Figure 2.15. The setup includes a wastewater

storage tank, a high-pressure pump, and a single cavitation reactor/set of

cavitation reactors with isolation valves along with tools for measurement

of pressure and flow. The reactors can be any hydrodynamic cavitating

PI

V4 V8

CR-1

TI

V5 V9

CR-2

V3 V6 V10

CR-3

By-pass

V2

V7 V11

PI Blank line

PI

V1

Feed pump

Return line

PI - Pressure indicator CR-1 : Cavitation reactor (vortex diode)

TI - Temperature indicator CR-2 : Cavitation reactor (orifice)

CR-3 : Cavitation reactor (venturi)

Figure 2.15 Experimental setup for cavitation studies on wastewater treatment.