Page 154 - Injection Molding Advanced Troubleshooting Guide

P. 154

142 16 Blush

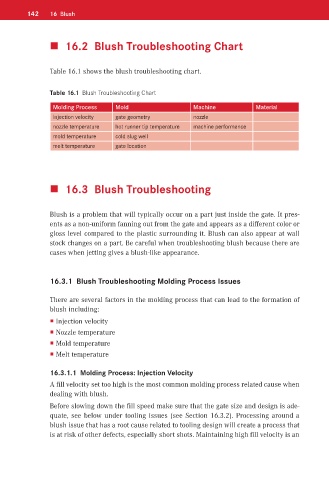

16.2 Blush Troubleshooting Chart

Table 16.1 shows the blush troubleshooting chart.

Table 16.1 Blush Troubleshooting Chart

Molding Process Mold Machine Material

injection velocity gate geometry nozzle

nozzle temperature hot runner tip temperature machine performance

mold temperature cold slug well

melt temperature gate location

16.3 Blush Troubleshooting

Blush is a problem that will typically occur on a part just inside the gate. It pres-

ents as a non-uniform fanning out from the gate and appears as a different color or

gloss level compared to the plastic surrounding it. Blush can also appear at wall

stock changes on a part. Be careful when troubleshooting blush because there are

cases when jetting gives a blush-like appearance.

16.3.1 Blush Troubleshooting Molding Process Issues

There are several factors in the molding process that can lead to the formation of

blush including:

Injection velocity

Nozzle temperature

Mold temperature

Melt temperature

16.3.1.1 Molding Process: Injection Velocity

A fill velocity set too high is the most common molding process related cause when

dealing with blush.

Before slowing down the fill speed make sure that the gate size and design is ade-

quate, see below under tooling issues (see Section 16.3.2). Processing around a

blush issue that has a root cause related to tooling design will create a process that

is at risk of other defects, especially short shots. Maintaining high fill velocity is an