Page 192 - Injection Molding Advanced Troubleshooting Guide

P. 192

182 20 Burns

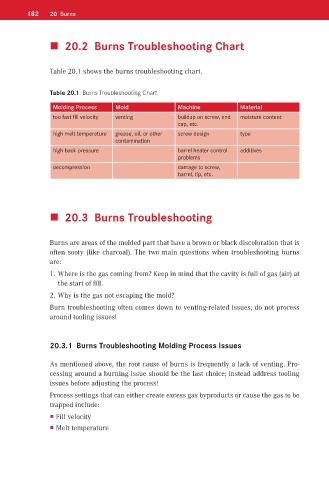

20.2 Burns Troubleshooting Chart

Table 20.1 shows the burns troubleshooting chart.

Table 20.1 Burns Troubleshooting Chart

Molding Process Mold Machine Material

too fast fill velocity venting buildup on screw, end moisture content

cap, etc.

high melt temperature grease, oil, or other screw design type

contamination

high back pressure barrel heater control additives

problems

decompression damage to screw,

barrel, tip, etc.

20.3 Burns Troubleshooting

Burns are areas of the molded part that have a brown or black discoloration that is

often sooty (like charcoal). The two main questions when troubleshooting burns

are:

1. Where is the gas coming from? Keep in mind that the cavity is full of gas (air) at

the start of fill.

2. Why is the gas not escaping the mold?

Burn troubleshooting often comes down to venting-related issues; do not process

around tooling issues!

20.3.1 Burns Troubleshooting Molding Process Issues

As mentioned above, the root cause of burns is frequently a lack of venting. Pro-

cessing around a burning issue should be the last choice; instead address tooling

issues before adjusting the process!

Process settings that can either create excess gas byproducts or cause the gas to be

trapped include:

Fill velocity

Melt temperature