Page 219 - Injection Molding Advanced Troubleshooting Guide

P. 219

210 23 Contamination

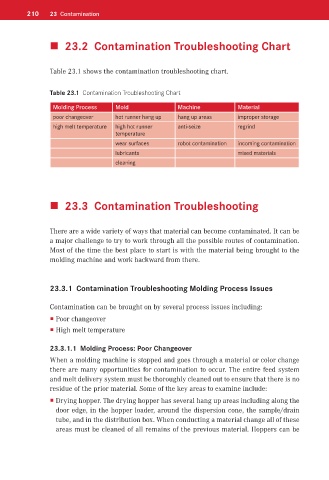

23.2 Contamination Troubleshooting Chart

Table 23.1 shows the contamination troubleshooting chart.

Table 23.1 Contamination Troubleshooting Chart

Molding Process Mold Machine Material

poor changeover hot runner hang up hang up areas improper storage

high melt temperature high hot runner anti-seize regrind

temperature

wear surfaces robot contamination incoming contamination

lubricants mixed materials

cleaning

23.3 Contamination Troubleshooting

There are a wide variety of ways that material can become contaminated. It can be

a major challenge to try to work through all the possible routes of contamination.

Most of the time the best place to start is with the material being brought to the

molding machine and work backward from there.

23.3.1 Contamination Troubleshooting Molding Process Issues

Contamination can be brought on by several process issues including:

Poor changeover

High melt temperature

23.3.1.1 Molding Process: Poor Changeover

When a molding machine is stopped and goes through a material or color change

there are many opportunities for contamination to occur. The entire feed system

and melt delivery system must be thoroughly cleaned out to ensure that there is no

residue of the prior material. Some of the key areas to examine include:

Drying hopper. The drying hopper has several hang up areas including along the

door edge, in the hopper loader, around the dispersion cone, the sample/drain

tube, and in the distribution box. When conducting a material change all of these

areas must be cleaned of all remains of the previous material. Hoppers can be