Page 223 - Injection Molding Advanced Troubleshooting Guide

P. 223

214 23 Contamination

Wear surfaces to keep an eye on include gibs, wear plates, die locks, cavity locking

angles, and shutoffs. The dust that appears is often an early sign of galling starting

so it is important to address any wear problems when they are detected.

23.3.2.4 Mold: Lubricants

Any of the lubricants used on a mold can lead to contamination of a molded part.

Whether it is grease or oil, when excess lubricants reach the cavity they can con-

taminate the part producing scrap.

A key item to watch for is over-lubricating a mold. Frequently when a mold comes

back from service, all moving components will have too much grease on them.

There can be cases where a mold will bleed grease for hours of molding, producing

nothing but scrap. Work with tooling sources to establish a standard method of

lubricating a mold. It is not as simple as smearing some grease on the pins; grease

should be lightly applied because over-greasing can lead to problems.

It is also important to find lubricants that work best for a given application. There

is a wide variety of lubricants available and some perform better for specific appli-

cations.

23.3.2.5 Mold: Cleaning

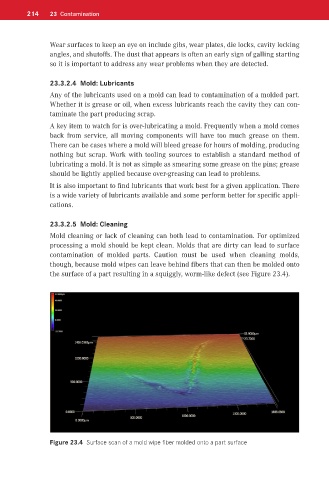

Mold cleaning or lack of cleaning can both lead to contamination. For optimized

processing a mold should be kept clean. Molds that are dirty can lead to surface

contamination of molded parts. Caution must be used when cleaning molds,

though, because mold wipes can leave behind fibers that can then be molded onto

the surface of a part resulting in a squiggly, worm-like defect (see Figure 23.4).

Figure 23.4 Surface scan of a mold wipe fiber molded onto a part surface