Page 243 - Injection Molding Advanced Troubleshooting Guide

P. 243

234 25 Delamination

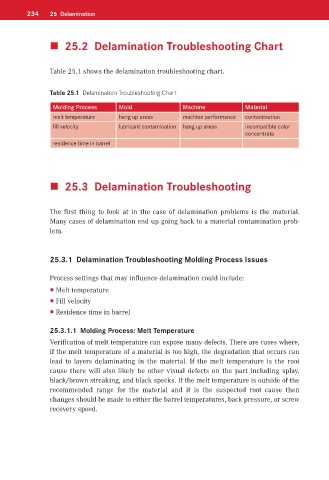

25.2 Delamination Troubleshooting Chart

Table 25.1 shows the delamination troubleshooting chart.

Table 25.1 Delamination Troubleshooting Chart

Molding Process Mold Machine Material

melt temperature hang up areas machine performance contamination

fill velocity lubricant contamination hang up areas incompatible color

concentrate

residence time in barrel

25.3 Delamination Troubleshooting

The first thing to look at in the case of delamination problems is the material.

Many cases of delamination end up going back to a material contamination prob-

lem.

25.3.1 Delamination Troubleshooting Molding Process Issues

Process settings that may influence delamination could include:

Melt temperature

Fill velocity

Residence time in barrel

25.3.1.1 Molding Process: Melt Temperature

Verification of melt temperature can expose many defects. There are cases where,

if the melt temperature of a material is too high, the degradation that occurs can

lead to layers delaminating in the material. If the melt temperature is the root

cause there will also likely be other visual defects on the part including splay,

black/brown streaking, and black specks. If the melt temperature is outside of the

recommended range for the material and it is the suspected root cause then

changes should be made to either the barrel temperatures, back pressure, or screw

recovery speed.