Page 248 - Injection Molding Advanced Troubleshooting Guide

P. 248

26 Dimensions

26.1 Description

One of the biggest ongoing potential problems in molding is dimensional control.

Plastic will tend to grow and shrink based on environmental conditions. Variations

during the processing of plastic will also lead to dimensional variation. Any given

part may end up too large or too small or even have one dimension that is accept-

able and another that is unacceptable.

Also known as: too big, too small, inconsistent, shrink

Mistaken identity: warp

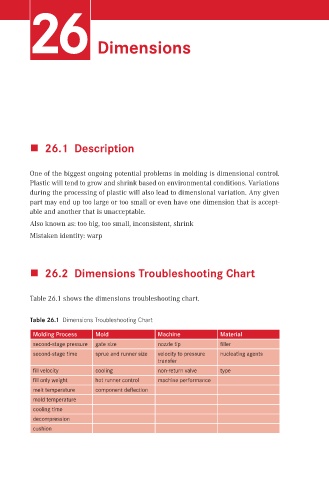

26.2 Dimensions Troubleshooting Chart

Table 26.1 shows the dimensions troubleshooting chart.

Table 26.1 Dimensions Troubleshooting Chart

Molding Process Mold Machine Material

second-stage pressure gate size nozzle tip filler

second-stage time sprue and runner size velocity to pressure nucleating agents

transfer

fill velocity cooling non-return valve type

fill only weight hot runner control machine performance

melt temperature component deflection

mold temperature

cooling time

decompression

cushion