Page 251 - Injection Molding Advanced Troubleshooting Guide

P. 251

242 26 Dimensions

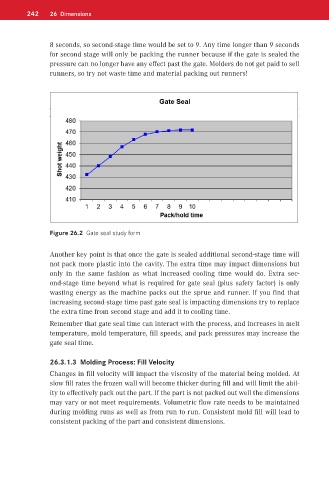

8 seconds, so second-stage time would be set to 9. Any time longer than 9 seconds

for second stage will only be packing the runner because if the gate is sealed the

pressure can no longer have any effect past the gate. Molders do not get paid to sell

runners, so try not waste time and material packing out runners!

Figure 26.2 Gate seal study form

Another key point is that once the gate is sealed additional second-stage time will

not pack more plastic into the cavity. The extra time may impact dimensions but

only in the same fashion as what increased cooling time would do. Extra sec-

ond-stage time beyond what is required for gate seal (plus safety factor) is only

wasting energy as the machine packs out the sprue and runner. If you find that

increasing second-stage time past gate seal is impacting dimensions try to replace

the extra time from second stage and add it to cooling time.

Remember that gate seal time can interact with the process, and increases in melt

temperature, mold temperature, fill speeds, and pack pressures may increase the

gate seal time.

26.3.1.3 Molding Process: Fill Velocity

Changes in fill velocity will impact the viscosity of the material being molded. At

slow fill rates the frozen wall will become thicker during fill and will limit the abil-

ity to effectively pack out the part. If the part is not packed out well the dimensions

may vary or not meet requirements. Volumetric flow rate needs to be maintained

during molding runs as well as from run to run. Consistent mold fill will lead to

consistent packing of the part and consistent dimensions.