Page 253 - Injection Molding Advanced Troubleshooting Guide

P. 253

244 26 Dimensions

®

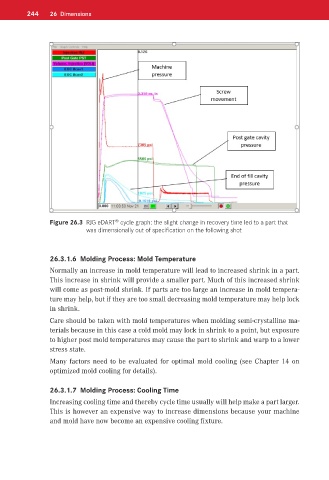

Figure 26.3 RJG eDART cycle graph: the slight change in recovery time led to a part that

was dimensionally out of specification on the following shot

26.3.1.6 Molding Process: Mold Temperature

Normally an increase in mold temperature will lead to increased shrink in a part.

This increase in shrink will provide a smaller part. Much of this increased shrink

will come as post-mold shrink. If parts are too large an increase in mold tempera-

ture may help, but if they are too small decreasing mold temperature may help lock

in shrink.

Care should be taken with mold temperatures when molding semi-crystalline ma-

terials because in this case a cold mold may lock in shrink to a point, but exposure

to higher post mold temperatures may cause the part to shrink and warp to a lower

stress state.

Many factors need to be evaluated for optimal mold cooling (see Chapter 14 on

optimized mold cooling for details).

26.3.1.7 Molding Process: Cooling Time

Increasing cooling time and thereby cycle time usually will help make a part larger.

This is however an expensive way to increase dimensions because your machine

and mold have now become an expensive cooling fixture.