Page 258 - Injection Molding Advanced Troubleshooting Guide

P. 258

26.3 Dimensions Troubleshooting 249

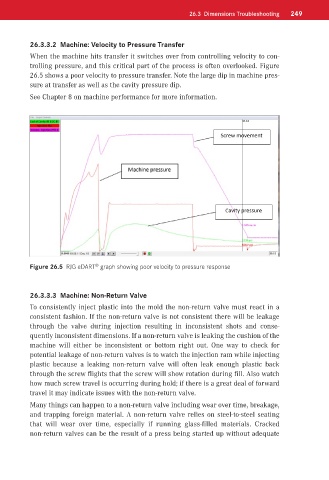

26.3.3.2 Machine: Velocity to Pressure Transfer

When the machine hits transfer it switches over from controlling velocity to con-

trolling pressure, and this critical part of the process is often overlooked. Figure

26.5 shows a poor velocity to pressure transfer. Note the large dip in machine pres-

sure at transfer as well as the cavity pressure dip.

See Chapter 8 on machine performance for more information.

®

Figure 26.5 RJG eDART graph showing poor velocity to pressure response

26.3.3.3 Machine: Non-Return Valve

To consistently inject plastic into the mold the non-return valve must react in a

consistent fashion. If the non-return valve is not consistent there will be leakage

through the valve during injection resulting in inconsistent shots and conse-

quently inconsistent dimensions. If a non-return valve is leaking the cushion of the

machine will either be inconsistent or bottom right out. One way to check for

potential leakage of non-return valves is to watch the injection ram while injecting

plastic because a leaking non-return valve will often leak enough plastic back

through the screw flights that the screw will show rotation during fill. Also watch

how much screw travel is occurring during hold; if there is a great deal of forward

travel it may indicate issues with the non-return valve.

Many things can happen to a non-return valve including wear over time, breakage,

and trapping foreign material. A non-return valve relies on steel-to-steel seating

that will wear over time, especially if running glass-filled materials. Cracked

non-return valves can be the result of a press being started up without adequate