Page 260 - Injection Molding Advanced Troubleshooting Guide

P. 260

26.3 Dimensions Troubleshooting 251

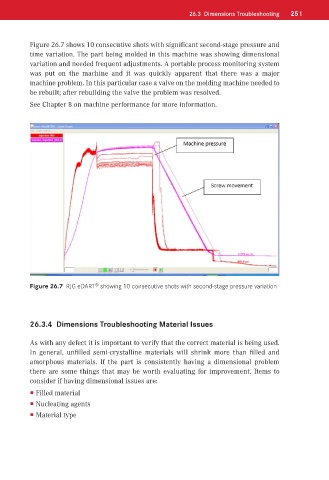

Figure 26.7 shows 10 consecutive shots with significant second-stage pressure and

time variation. The part being molded in this machine was showing dimensional

variation and needed frequent adjustments. A portable process monitoring system

was put on the machine and it was quickly apparent that there was a major

machine problem. In this particular case a valve on the molding machine needed to

be rebuilt; after rebuilding the valve the problem was resolved.

See Chapter 8 on machine performance for more information.

Figure 26.7 RJG eDART showing 10 consecutive shots with second-stage pressure variation

®

26.3.4 Dimensions Troubleshooting Material Issues

As with any defect it is important to verify that the correct material is being used.

In general, unfilled semi-crystalline materials will shrink more than filled and

amorphous materials. If the part is consistently having a dimensional problem

there are some things that may be worth evaluating for improvement. Items to

consider if having dimensional issues are:

Filled material

Nucleating agents

Material type