Page 259 - Injection Molding Advanced Troubleshooting Guide

P. 259

250 26 Dimensions

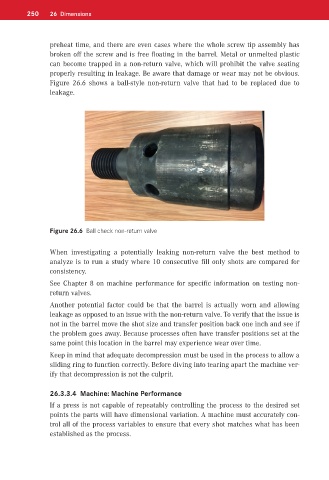

preheat time, and there are even cases where the whole screw tip assembly has

broken off the screw and is free floating in the barrel. Metal or unmelted plastic

can become trapped in a non-return valve, which will prohibit the valve seating

properly resulting in leakage. Be aware that damage or wear may not be obvious.

Figure 26.6 shows a ball-style non-return valve that had to be replaced due to

leakage.

Figure 26.6 Ball check non-return valve

When investigating a potentially leaking non-return valve the best method to

analyze is to run a study where 10 consecutive fill only shots are compared for

consistency.

See Chapter 8 on machine performance for specific information on testing non-

return valves.

Another potential factor could be that the barrel is actually worn and allowing

leakage as opposed to an issue with the non-return valve. To verify that the issue is

not in the barrel move the shot size and transfer position back one inch and see if

the problem goes away. Because processes often have transfer positions set at the

same point this location in the barrel may experience wear over time.

Keep in mind that adequate decompression must be used in the process to allow a

sliding ring to function correctly. Before diving into tearing apart the machine ver-

ify that decompression is not the culprit.

26.3.3.4 Machine: Machine Performance

If a press is not capable of repeatably controlling the process to the desired set

points the parts will have dimensional variation. A machine must accurately con-

trol all of the process variables to ensure that every shot matches what has been

established as the process.