Page 268 - Injection Molding Advanced Troubleshooting Guide

P. 268

260 27 Excessive Cycle Time

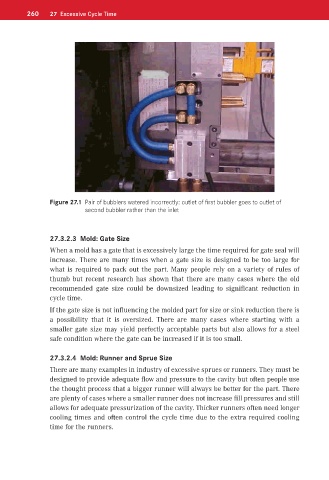

Figure 27.1 Pair of bubblers watered incorrectly: outlet of first bubbler goes to outlet of

second bubbler rather than the inlet

27.3.2.3 Mold: Gate Size

When a mold has a gate that is excessively large the time required for gate seal will

increase. There are many times when a gate size is designed to be too large for

what is required to pack out the part. Many people rely on a variety of rules of

thumb but recent research has shown that there are many cases where the old

recommended gate size could be downsized leading to significant reduction in

cycle time.

If the gate size is not influencing the molded part for size or sink reduction there is

a possibility that it is oversized. There are many cases where starting with a

smaller gate size may yield perfectly acceptable parts but also allows for a steel

safe condition where the gate can be increased if it is too small.

27.3.2.4 Mold: Runner and Sprue Size

There are many examples in industry of excessive sprues or runners. They must be

designed to provide adequate flow and pressure to the cavity but often people use

the thought process that a bigger runner will always be better for the part. There

are plenty of cases where a smaller runner does not increase fill pressures and still

allows for adequate pressurization of the cavity. Thicker runners often need longer

cooling times and often control the cycle time due to the extra required cooling

time for the runners.