Page 307 - Injection Molding Advanced Troubleshooting Guide

P. 307

31.3 Flow Lines Troubleshooting 301

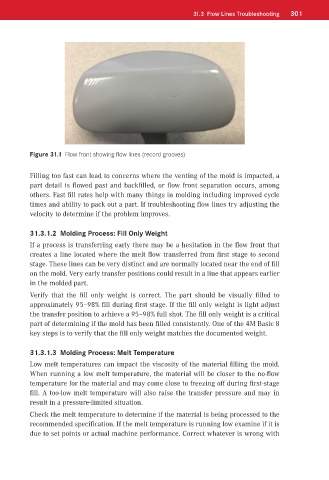

Figure 31.1 Flow front showing flow lines (record grooves)

Filling too fast can lead to concerns where the venting of the mold is impacted, a

part detail is flowed past and backfilled, or flow front separation occurs, among

others. Fast fill rates help with many things in molding including improved cycle

times and ability to pack out a part. If troubleshooting flow lines try adjusting the

velocity to determine if the problem improves.

31.3.1.2 Molding Process: Fill Only Weight

If a process is transferring early there may be a hesitation in the flow front that

creates a line located where the melt flow transferred from first stage to second

stage. These lines can be very distinct and are normally located near the end of fill

on the mold. Very early transfer positions could result in a line that appears earlier

in the molded part.

Verify that the fill only weight is correct. The part should be visually filled to

approximately 95–98% fill during first stage. If the fill only weight is light adjust

the transfer position to achieve a 95–98% full shot. The fill only weight is a critical

part of determining if the mold has been filled consistently. One of the 4M Basic 8

key steps is to verify that the fill only weight matches the documented weight.

31.3.1.3 Molding Process: Melt Temperature

Low melt temperatures can impact the viscosity of the material filling the mold.

When running a low melt temperature, the material will be closer to the no-flow

temperature for the material and may come close to freezing off during first-stage

fill. A too-low melt temperature will also raise the transfer pressure and may in

result in a pressure-limited situation.

Check the melt temperature to determine if the material is being processed to the

recommended specification. If the melt temperature is running low examine if it is

due to set points or actual machine performance. Correct whatever is wrong with