Page 325 - Injection Molding Advanced Troubleshooting Guide

P. 325

320 33 Gloss Variation

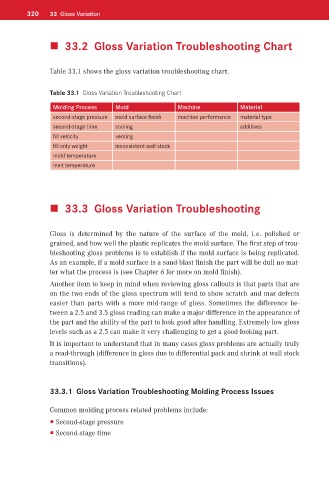

33.2 Gloss Variation Troubleshooting Chart

Table 33.1 shows the gloss variation troubleshooting chart.

Table 33.1 Gloss Variation Troubleshooting Chart

Molding Process Mold Machine Material

second-stage pressure mold surface finish machine performance material type

second-stage time cooling additives

fill velocity venting

fill only weight inconsistent wall stock

mold temperature

melt temperature

33.3 Gloss Variation Troubleshooting

Gloss is determined by the nature of the surface of the mold, i. e. polished or

grained, and how well the plastic replicates the mold surface. The first step of trou-

bleshooting gloss problems is to establish if the mold surface is being replicated.

As an example, if a mold surface is a sand-blast finish the part will be dull no mat-

ter what the process is (see Chapter 6 for more on mold finish).

Another item to keep in mind when reviewing gloss callouts is that parts that are

on the two ends of the gloss spectrum will tend to show scratch and mar defects

easier than parts with a more mid-range of gloss. Sometimes the difference be-

tween a 2.5 and 3.5 gloss reading can make a major difference in the appearance of

the part and the ability of the part to look good after handling. Extremely low gloss

levels such as a 2.5 can make it very challenging to get a good-looking part.

It is important to understand that in many cases gloss problems are actually truly

a read-through (difference in gloss due to differential pack and shrink at wall stock

transitions).

33.3.1 Gloss Variation Troubleshooting Molding Process Issues

Common molding process related problems include:

Second-stage pressure

Second-stage time