Page 328 - Injection Molding Advanced Troubleshooting Guide

P. 328

33.3 Gloss Variation Troubleshooting 323

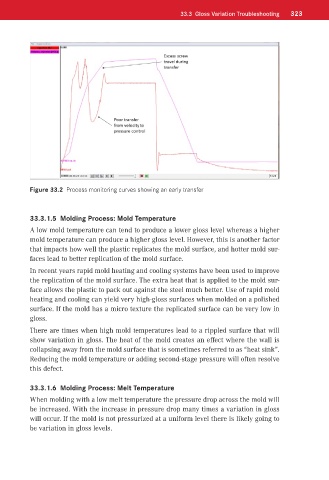

Figure 33.2 Process monitoring curves showing an early transfer

33.3.1.5 Molding Process: Mold Temperature

A low mold temperature can tend to produce a lower gloss level whereas a higher

mold temperature can produce a higher gloss level. However, this is another factor

that impacts how well the plastic replicates the mold surface, and hotter mold sur-

faces lead to better replication of the mold surface.

In recent years rapid mold heating and cooling systems have been used to improve

the replication of the mold surface. The extra heat that is applied to the mold sur-

face allows the plastic to pack out against the steel much better. Use of rapid mold

heating and cooling can yield very high-gloss surfaces when molded on a polished

surface. If the mold has a micro texture the replicated surface can be very low in

gloss.

There are times when high mold temperatures lead to a rippled surface that will

show variation in gloss. The heat of the mold creates an effect where the wall is

collapsing away from the mold surface that is sometimes referred to as “heat sink”.

Reducing the mold temperature or adding second-stage pressure will often resolve

this defect.

33.3.1.6 Molding Process: Melt Temperature

When molding with a low melt temperature the pressure drop across the mold will

be increased. With the increase in pressure drop many times a variation in gloss

will occur. If the mold is not pressurized at a uniform level there is likely going to

be variation in gloss levels.