Page 331 - Injection Molding Advanced Troubleshooting Guide

P. 331

326 33 Gloss Variation

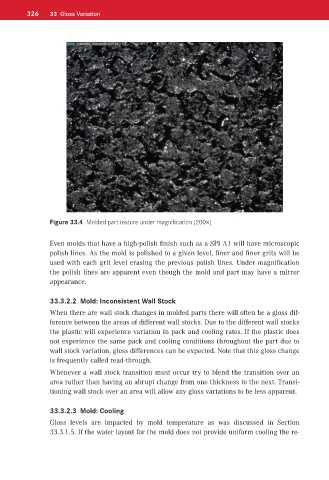

Figure 33.4 Molded part texture under magnification (200×)

Even molds that have a high-polish finish such as a SPI A1 will have microscopic

polish lines. As the mold is polished to a given level, finer and finer grits will be

used with each grit level erasing the previous polish lines. Under magnification

the polish lines are apparent even though the mold and part may have a mirror

appearance.

33.3.2.2 Mold: Inconsistent Wall Stock

When there are wall stock changes in molded parts there will often be a gloss dif-

ference between the areas of different wall stocks. Due to the different wall stocks

the plastic will experience variation in pack and cooling rates. If the plastic does

not experience the same pack and cooling conditions throughout the part due to

wall stock variation, gloss differences can be expected. Note that this gloss change

is frequently called read-through.

Whenever a wall stock transition must occur try to blend the transition over an

area rather than having an abrupt change from one thickness to the next. Transi-

tioning wall stock over an area will allow any gloss variations to be less apparent.

33.3.2.3 Mold: Cooling

Gloss levels are impacted by mold temperature as was discussed in Section

33.3.1.5. If the water layout for the mold does not provide uniform cooling the re-