Page 360 - Injection Molding Advanced Troubleshooting Guide

P. 360

356 37 Pin Push

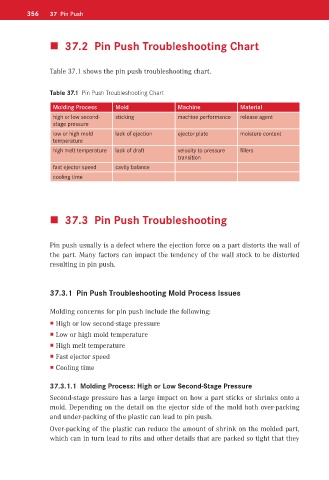

37.2 Pin Push Troubleshooting Chart

Table 37.1 shows the pin push troubleshooting chart.

Table 37.1 Pin Push Troubleshooting Chart

Molding Process Mold Machine Material

high or low second- sticking machine performance release agent

stage pressure

low or high mold lack of ejection ejector plate moisture content

temperature

high melt temperature lack of draft velocity to pressure fillers

transition

fast ejector speed cavity balance

cooling time

37.3 Pin Push Troubleshooting

Pin push usually is a defect where the ejection force on a part distorts the wall of

the part. Many factors can impact the tendency of the wall stock to be distorted

resulting in pin push.

37.3.1 Pin Push Troubleshooting Mold Process Issues

Molding concerns for pin push include the following:

High or low second-stage pressure

Low or high mold temperature

High melt temperature

Fast ejector speed

Cooling time

37.3.1.1 Molding Process: High or Low Second-Stage Pressure

Second-stage pressure has a large impact on how a part sticks or shrinks onto a

mold. Depending on the detail on the ejector side of the mold both over-packing

and under-packing of the plastic can lead to pin push.

Over-packing of the plastic can reduce the amount of shrink on the molded part,

which can in turn lead to ribs and other details that are packed so tight that they