Page 365 - Injection Molding Advanced Troubleshooting Guide

P. 365

37.3 Pin Push Troubleshooting 361

37.3.3.3 Machine: Velocity to Pressure Transition

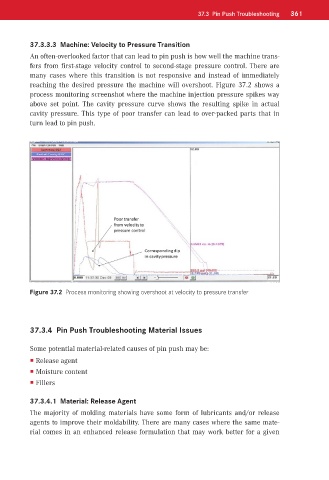

An often-overlooked factor that can lead to pin push is how well the machine trans-

fers from first-stage velocity control to second-stage pressure control. There are

many cases where this transition is not responsive and instead of immediately

reaching the desired pressure the machine will overshoot. Figure 37.2 shows a

process monitoring screenshot where the machine injection pressure spikes way

above set point. The cavity pressure curve shows the resulting spike in actual

cavity pressure. This type of poor transfer can lead to over-packed parts that in

turn lead to pin push.

Figure 37.2 Process monitoring showing overshoot at velocity to pressure transfer

37.3.4 Pin Push Troubleshooting Material Issues

Some potential material-related causes of pin push may be:

Release agent

Moisture content

Fillers

37.3.4.1 Material: Release Agent

The majority of molding materials have some form of lubricants and/or release

agents to improve their moldability. There are many cases where the same mate-

rial comes in an enhanced release formulation that may work better for a given