Page 368 - Injection Molding Advanced Troubleshooting Guide

P. 368

364 38 Read-through

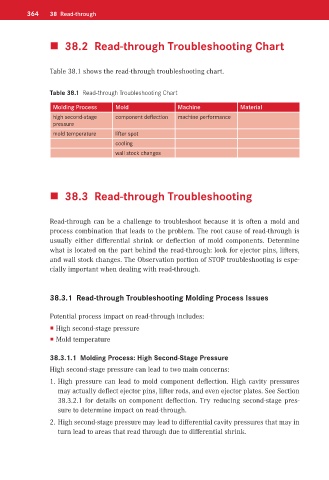

38.2 Read-through Troubleshooting Chart

Table 38.1 shows the read-through troubleshooting chart.

Table 38.1 Read-through Troubleshooting Chart

Molding Process Mold Machine Material

high second-stage component deflection machine performance

pressure

mold temperature lifter spot

cooling

wall stock changes

38.3 Read-through Troubleshooting

Read-through can be a challenge to troubleshoot because it is often a mold and

process combination that leads to the problem. The root cause of read-through is

usually either differential shrink or deflection of mold components. Determine

what is located on the part behind the read-through: look for ejector pins, lifters,

and wall stock changes. The Observation portion of STOP troubleshooting is espe-

cially important when dealing with read-through.

38.3.1 Read-through Troubleshooting Molding Process Issues

Potential process impact on read-through includes:

High second-stage pressure

Mold temperature

38.3.1.1 Molding Process: High Second-Stage Pressure

High second-stage pressure can lead to two main concerns:

1. High pressure can lead to mold component deflection. High cavity pressures

may actually deflect ejector pins, lifter rods, and even ejector plates. See Section

38.3.2.1 for details on component deflection. Try reducing second-stage pres-

sure to determine impact on read-through.

2. High second-stage pressure may lead to differential cavity pressures that may in

turn lead to areas that read through due to differential shrink.