Page 373 - Injection Molding Advanced Troubleshooting Guide

P. 373

370 39 Scuffs and Scratches

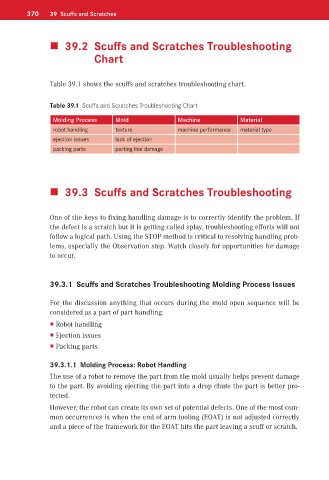

39.2 Scuffs and Scratches Troubleshooting

Chart

Table 39.1 shows the scuffs and scratches troubleshooting chart.

Table 39.1 Scuffs and Scratches Troubleshooting Chart

Molding Process Mold Machine Material

robot handling texture machine performance material type

ejection issues lack of ejection

packing parts parting line damage

39.3 Scuffs and Scratches Troubleshooting

One of the keys to fixing handling damage is to correctly identify the problem. If

the defect is a scratch but it is getting called splay, troubleshooting efforts will not

follow a logical path. Using the STOP method is critical to resolving handling prob-

lems, especially the Observation step. Watch closely for opportunities for damage

to occur.

39.3.1 Scuffs and Scratches Troubleshooting Molding Process Issues

For the discussion anything that occurs during the mold open sequence will be

considered as a part of part handling:

Robot handling

Ejection issues

Packing parts

39.3.1.1 Molding Process: Robot Handling

The use of a robot to remove the part from the mold usually helps prevent damage

to the part. By avoiding ejecting the part into a drop chute the part is better pro-

tected.

However, the robot can create its own set of potential defects. One of the most com-

mon occurrences is when the end of arm tooling (EOAT) is not adjusted correctly

and a piece of the framework for the EOAT hits the part leaving a scuff or scratch.