Page 250 - Instrumentation Reference Book 3E

P. 250

234 Microprocessor-based and intelligent transmitters

Fieldbus

configuration

& monitoring

Control

pressure

transmitters

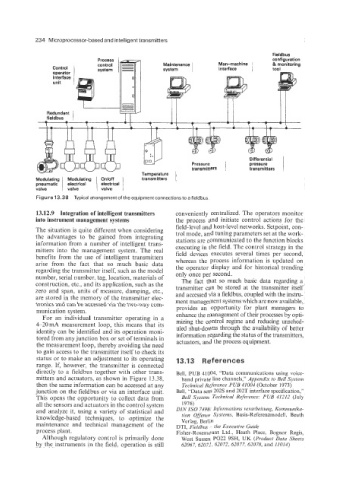

Figure 13.38 Typical arrangement of the equipment connections to a fieldbus

13.12.9 Integration of intelligent transmitters conveniently centralized. The operators monitor

into instrument management systems the process and initiate control actions for the

field-level and host-level networks. Setpoint, con-

The situation is quite different when considering trol mode, and tuning parameters set at the work-

the advantages to be gained from integrating stations are communicated to the function blocks

information from a number of intelligent trans- executing in the field. The control strategy in the

mitters into the management system. The real field devices executes several times per second,

benefits from the use of intelligent transmitters whereas the process information is updated on

arise from the fact that so much basic data the operator display and for historical trending

regarding the transmitter itself, such as the model only once per second.

number, serial number, tag, location, materials of The fact that so much basic data regarding a

construction, etc., and its application, such as the transmitter can be stored at the transmitter itself

zero and span, units of measure. damping, etc., and accessed via a fieldbus, coupled with the instru-

are stored in the memory of the transmitter elec- ment management systems which are now available,

tronics and can be accessed via the two-way com- provides an opportunity for plant managers to

munication system. enhance the management of their processes by opti-

For an individual transmitter operating in a

4-20 mA measurement loop, this means that its mizing the control regime and reducing unsched-

uled shut-downs through the availability of better

identity can be identified and its operation moni- information regarding the status of the transmitters,

tored from any junction box or set of terminals in actuators, and the process equipment.

the measurement loop, thereby avoiding the need

to gain access to the transmitter itself to check its

status or to make an adjustment to its operating 13.13 References

range. If, however, the transmitter is connected

directly to a fieldbus together with other trans- Bell. PUB 41004, “Data communications using voice-

mitters and actuators, as shown in Figure 13.38, band private line channels,” Appendix to Bell System

then the same information can be accessed at any Teclznicul Reference PUB 41004 (October 1973)

junction on the fieldbus or via an interface unit. Bell, “Data sets 202s and 202T interface specification,”

This opens the opportunity to collect data from Bell S-vstenz Technical Reference: PUB 41212 (July

all the sensors and actuators in the control system 1976)

and analyze it. using a variety of statistical and DIN IS0 7498: Inforniations verurbeitung, Kommtoziku-

tion Offener Systems, Basis-Referenzmodell, Beuth

knowledge-based techniques, to optimize the Verlag, Berlin

maintenance and technical management of the DTI, Fieldbus ~ the Execcrtive Guide

process plant. Fisher-Rosemount Ltd., Heath Place, Bognor Regis,

Although regulatory control is primarily done West Sussex PO22 9SH, UK (Product Data Sheets

by the instruments in the field, operation is still 62067, 620 71, 62072, 620 77, 620 78, and I IO1 4)