Page 267 -

P. 267

Processes in Warehouse Management 249

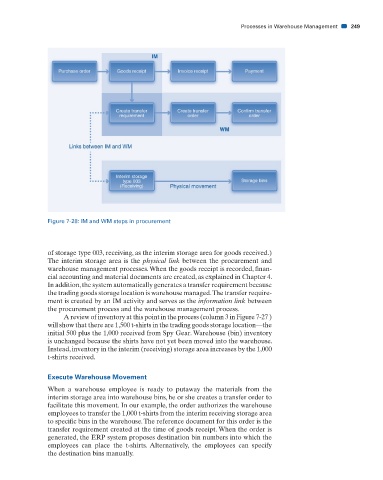

Figure 7-28: IM and WM steps in procurement

of storage type 003, receiving, as the interim storage area for goods received.)

The interim storage area is the physical link between the procurement and

warehouse management processes. When the goods receipt is recorded, fi nan-

cial accounting and material documents are created, as explained in Chapter 4.

In addition, the system automatically generates a transfer requirement because

the trading goods storage location is warehouse managed. The transfer require-

ment is created by an IM activity and serves as the information link between

the procurement process and the warehouse management process.

A review of inventory at this point in the process (column 3 in Figure 7-27 )

will show that there are 1,500 t-shirts in the trading goods storage location—the

initial 500 plus the 1,000 received from Spy Gear. Warehouse (bin) inventory

is unchanged because the shirts have not yet been moved into the warehouse.

Instead, inventory in the interim (receiving) storage area increases by the 1,000

t-shirts received.

Execute Warehouse Movement

When a warehouse employee is ready to putaway the materials from the

interim storage area into warehouse bins, he or she creates a transfer order to

facilitate this movement. In our example, the order authorizes the warehouse

employees to transfer the 1,000 t-shirts from the interim receiving storage area

to specifi c bins in the warehouse. The reference document for this order is the

transfer requirement created at the time of goods receipt. When the order is

generated, the ERP system proposes destination bin numbers into which the

employees can place the t-shirts. Alternatively, the employees can specify

the destination bins manually.

31/01/11 6:41 AM

CH007.indd 249 31/01/11 6:41 AM

CH007.indd 249