Page 84 - Materials Chemistry, Second Edition

P. 84

L1644_C02.fm Page 61 Tuesday, October 21, 2003 3:07 PM

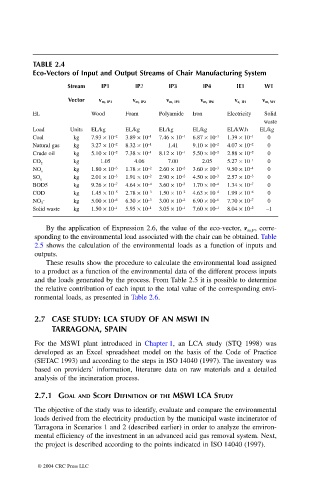

TABLE 2.4

Eco-Vectors of Input and Output Streams of Chair Manufacturing System

Stream IP1 IP2 IP3 IP4 IE1 W1

Vector v m, IP1 v m, IP2 v m, IP3 v m, IP4 v e, IE1 v m, W1

EL Wood Foam Polyamide Iron Electricity Solid

waste

Load Units EL/kg EL/kg EL/kg EL/kg EL/kW.h EL/kg

Coal kg 7.93 × 10 –2 3.89 × 10 –1 7.46 × 10 –1 6.87 × 10 –1 1.39 × 10 –1 0

Natural gas kg 3.27 × 10 –2 8.32 × 10 –1 1.41 9.10 × 10 –2 4.07 × 10 –2 0

Crude oil kg 5.10 × 10 –2 7.38 × 10 –1 8.12 × 10 –1 5.50 × 10 –2 2.88 × 10 –2 0

kg 1.05 4.06 7.00 2.05 5.27 × 10 –1 0

CO 2

kg 1.80 × 10 –3 1.78 × 10 –2 2.60 × 10 –2 3.60 × 10 –3 9.50 × 10 –4 0

NO x

kg 2.01 × 10 –3 1.91 × 10 –2 2.90 × 10 –2 4.50 × 10 –3 2.57 × 10 –3 0

SO x

BOD5 kg 9.26 × 10 –7 4.64 × 10 –4 3.60 × 10 –3 1.70 × 10 –4 1.34 × 10 –7 0

COD kg 1.45 × 10 –5 2.78 × 10 –3 1.50 × 10 –2 4.63 × 10 –4 1.99 × 10 –6 0

– kg 5.00 × 10 –6 6.30 × 10 –3 3.00 × 10 –2 6.90 × 10 –6 7.70 × 10 –7 0

NO 3

Solid waste kg 1.50 × 10 –1 5.95 × 10 –1 3.05 × 10 –1 7.60 × 10 –1 8.04 × 10 –2 –1

By the application of Expression 2.6, the value of the eco-vector, v , corre-

m,P

sponding to the environmental load associated with the chair can be obtained. Table

2.5 shows the calculation of the environmental loads as a function of inputs and

outputs.

These results show the procedure to calculate the environmental load assigned

to a product as a function of the environmental data of the different process inputs

and the loads generated by the process. From Table 2.5 it is possible to determine

the relative contribution of each input to the total value of the corresponding envi-

ronmental loads, as presented in Table 2.6.

2.7 CASE STUDY: LCA STUDY OF AN MSWI IN

TARRAGONA, SPAIN

For the MSWI plant introduced in Chapter 1, an LCA study (STQ 1998) was

developed as an Excel spreadsheet model on the basis of the Code of Practice

(SETAC 1993) and according to the steps in ISO 14040 (1997). The inventory was

based on providers’ information, literature data on raw materials and a detailed

analysis of the incineration process.

2.7.1 GOAL AND SCOPE DEFINITION OF THE MSWI LCA STUDY

The objective of the study was to identify, evaluate and compare the environmental

loads derived from the electricity production by the municipal waste incinerator of

Tarragona in Scenarios 1 and 2 (described earlier) in order to analyze the environ-

mental efficiency of the investment in an advanced acid gas removal system. Next,

the project is described according to the points indicated in ISO 14040 (1997).

© 2004 CRC Press LLC