Page 56 - Intelligent Digital Oil And Gas Fields

P. 56

reduction

well

reserve

Low-/mid-/

engineer’s

time-savings

incremental

Significant

HSE

benefits.

per

Economics

NPT/

high-

IWC

gain

98%

and

in

•

•

•

Operations—day-to-day

standards

inte-

platform.

application

data

engineering,

production,

an

operations.

workflows

diverse

system

an

Diatomite

system

open

common

and

i-Connect

integrated

facilities,

DOF

reservoir

field

through

i-DOT

sources

grated

Practices

and

and

33

•

•

•

multifunctio-

architecture

support

to

IT

Integrated

Proactive

approach

team

problem

solving.

Robust

model.

Practices

and

and

nal

i-field (2005), Basin), (Permian US and Others), (Agbami Field Nigeria Locations: for Results Operational Notional and Best Workflow Automated Best DOF Introduction to Digital Oil and Gas Field Systems 5/10/18 of execution and planning health system MMSTBO. diatomite thermal of monitoring over Saved • operations.

•

•

•

equipment

com-

valves

lines,

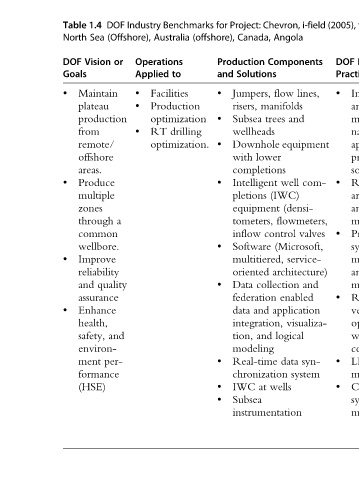

Chevron, Angola Components flow manifolds and trees lower well (IWC) (densi- flowmeters, control (Microsoft, service- architecture) collection enabled application logical and data wells instrumentation

Project: Canada, Production Solutions Jumpers, risers, Subsea wellheads Downhole with completions Intelligent pletions equipment tometers, inflow Software multitiered, oriented Data federation and data integration, tion, modeling Real-time chronization at IWC Subsea

for (offshore), and • • • • • • • • •

Benchmarks Australia to Facilities Production optimization drilling optimization.

Industry Operations Applied • • RT •

DOF (Offshore), or a quality and per-

1.4 Sea Vision Maintain plateau production from remote/ offshore areas. Produce multiple zones through common wellbore. Improve reliability and assurance Enhance health, safety, environ- ment formance (HSE)

Table North DOF Goals • • • •