Page 52 - Intelligent Digital Oil And Gas Fields

P. 52

and

several

production

operation

years

lift

Economics

Results

water

gas

2

breakthrough

oil

by

by

Optimized

Increased

Increased

reliability

(Brunei)

Operational

through

Delayed

15%

percent

Notional

by

•

•

•

•

for

model-

Implementation

Petex

methodology

Closed-loop

visualization

visualization

Accelerated

Best

Integrated

using

Software

reservoir

system

Workflow

Practices

ing

•

•

•

•

optimization

process

moni-

field-

and

Real-time

Real-time

Test

test

toring

Best

Practices

using

ware

Well

well

well

RT

DOF

•

•

•

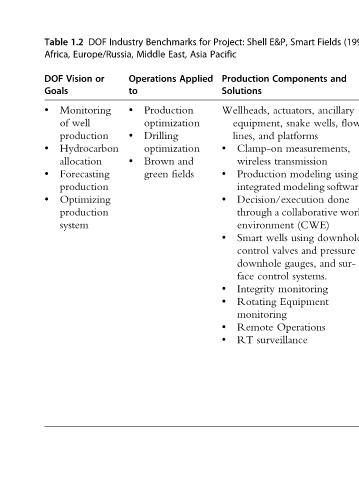

(1998), West US, Worldwide: and Sea North Field, Nelson I Mark Fields: for Automated Introduction to Digital Oil and Gas Field Systems manual Reduced • asset integrated historian day per 4h by data management acquisi- Data • efficiency Increased • statisti- In-house • and tion sur- automatic through d

work

software

flow

using

Fields and ancillary wells, measurements, done downhole pressure and

Smart Components actuators, snake platforms transmission modeling modeling collaborative (CWE) using and gauges, systems. monitoring Equipment Operations

E&P, Decision/execution a wells valves control surveillance

Shell Production Wellheads, equipment, and lines, Clamp-on wireless Production integrated through environment Smart control downhole face Integrity Rotating monitoring Remote RT

Project: Pacific Solutions • • • • • • • •

for Asia Applied

Benchmarks East, Middle Operations Production optimization Drilling optimization and Brown fields green

Industry to • • •

DOF Europe/Russia, or Hydrocarbon

1.2 Vision Monitoring well production allocation Forecasting production Optimizing production system

Table Africa, DOF Goals • of • • •