Page 322 - Intro Predictive Maintenance

P. 322

Failure-Mode Analysis 313

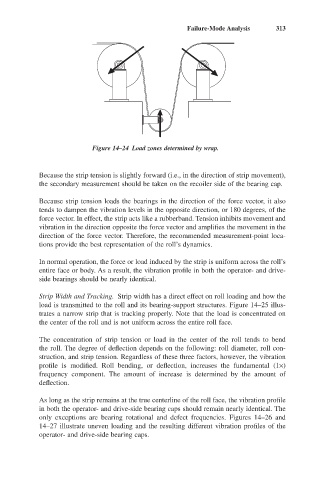

Figure 14–24 Load zones determined by wrap.

Because the strip tension is slightly forward (i.e., in the direction of strip movement),

the secondary measurement should be taken on the recoiler side of the bearing cap.

Because strip tension loads the bearings in the direction of the force vector, it also

tends to dampen the vibration levels in the opposite direction, or 180 degrees, of the

force vector. In effect, the strip acts like a rubberband. Tension inhibits movement and

vibration in the direction opposite the force vector and amplifies the movement in the

direction of the force vector. Therefore, the recommended measurement-point loca-

tions provide the best representation of the roll’s dynamics.

In normal operation, the force or load induced by the strip is uniform across the roll’s

entire face or body. As a result, the vibration profile in both the operator- and drive-

side bearings should be nearly identical.

Strip Width and Tracking. Strip width has a direct effect on roll loading and how the

load is transmitted to the roll and its bearing-support structures. Figure 14–25 illus-

trates a narrow strip that is tracking properly. Note that the load is concentrated on

the center of the roll and is not uniform across the entire roll face.

The concentration of strip tension or load in the center of the roll tends to bend

the roll. The degree of deflection depends on the following: roll diameter, roll con-

struction, and strip tension. Regardless of these three factors, however, the vibration

profile is modified. Roll bending, or deflection, increases the fundamental (1¥)

frequency component. The amount of increase is determined by the amount of

deflection.

As long as the strip remains at the true centerline of the roll face, the vibration profile

in both the operator- and drive-side bearing caps should remain nearly identical. The

only exceptions are bearing rotational and defect frequencies. Figures 14–26 and

14–27 illustrate uneven loading and the resulting different vibration profiles of the

operator- and drive-side bearing caps.