Page 369 - Intro Predictive Maintenance

P. 369

360 An Introduction to Predictive Maintenance

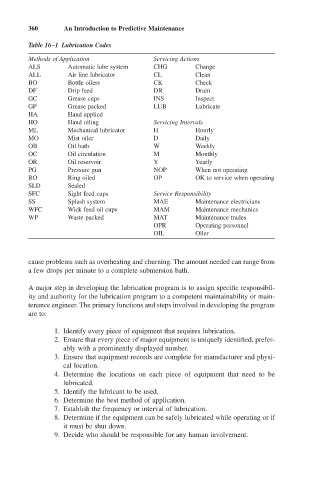

Table 16–1 Lubrication Codes

Methods of Application Servicing Actions

ALS Automatic lube system CHG Change

ALL Air line lubricator CL Clean

BO Bottle oilers CK Check

DF Drip feed DR Drain

GC Grease cups INS Inspect

GP Grease packed LUB Lubricate

HA Hand applied

HO Hand oiling Servicing Intervals

ML Mechanical lubricator H Hourly

MO Mist oiler D Daily

OB Oil bath W Weekly

OC Oil circulation M Monthly

OR Oil reservoir Y Yearly

PG Pressure gun NOP When not operating

RO Ring oiled OP OK to service when operating

SLD Sealed

SFC Sight feed cups Service Responsibility

SS Splash system MAE Maintenance electricians

WFC Wick feed oil cups MAM Maintenance mechanics

WP Waste packed MAT Maintenance trades

OPR Operating personnel

OIL Oiler

cause problems such as overheating and churning. The amount needed can range from

a few drops per minute to a complete submersion bath.

A major step in developing the lubrication program is to assign specific responsibil-

ity and authority for the lubrication program to a competent maintainability or main-

tenance engineer. The primary functions and steps involved in developing the program

are to:

1. Identify every piece of equipment that requires lubrication.

2. Ensure that every piece of major equipment is uniquely identified, prefer-

ably with a prominently displayed number.

3. Ensure that equipment records are complete for manufacturer and physi-

cal location.

4. Determine the locations on each piece of equipment that need to be

lubricated.

5. Identify the lubricant to be used.

6. Determine the best method of application.

7. Establish the frequency or interval of lubrication.

8. Determine if the equipment can be safely lubricated while operating or if

it must be shut down.

9. Decide who should be responsible for any human involvement.