Page 370 - Intro Predictive Maintenance

P. 370

A Total-Plant Predictive Maintenance Program 361

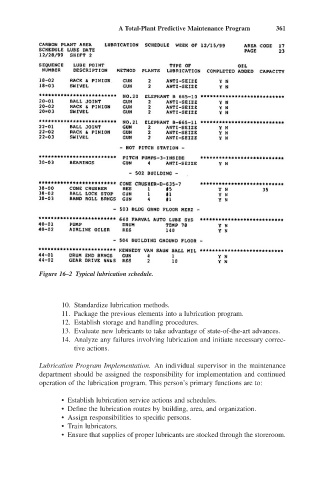

Figure 16–2 Typical lubrication schedule.

10. Standardize lubrication methods.

11. Package the previous elements into a lubrication program.

12. Establish storage and handling procedures.

13. Evaluate new lubricants to take advantage of state-of-the-art advances.

14. Analyze any failures involving lubrication and initiate necessary correc-

tive actions.

Lubrication Program Implementation. An individual supervisor in the maintenance

department should be assigned the responsibility for implementation and continued

operation of the lubrication program. This person’s primary functions are to:

• Establish lubrication service actions and schedules.

• Define the lubrication routes by building, area, and organization.

• Assign responsibilities to specific persons.

• Train lubricators.

• Ensure that supplies of proper lubricants are stocked through the storeroom.