Page 26 - Introduction to Colloid and Surface Chemistry

P. 26

The colloidal state 11

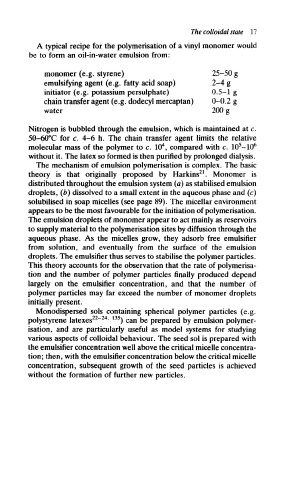

A typical recipe for the polymerisation of a vinyl monomer would

be to form an oil-in-water emulsion from:

monomer (e.g. styrene) 25-50 g

emulsifying agent (e.g. fatty acid soap) 2-4 g

initiator (e.g. potassium persulphate) 0.5-1 g

chain transfer agent (e.g. dodecyl mercaptan) 0-0.2 g

water 200 g

Nitrogen is bubbled through the emulsion, which is maintained at c,

50-60°C for c. 4-6 h. The chain transfer agent limits the relative

4

5

molecular mass of the polymer to c. 10 , compared with c. 10 -10 6

without it. The latex so formed is then purified by prolonged dialysis.

The mechanism of emulsion polymerisation is complex. The basic

21

theory is that originally proposed by Harkins . Monomer is

distributed throughout the emulsion system (a) as stabilised emulsion

droplets, (b) dissolved to a small extent in the aqueous phase and (c)

solubilised in soap micelles (see page 89). The micellar environment

appears to be the most favourable for the initiation of polymerisation.

The emulsion droplets of monomer appear to act mainly as reservoirs

to supply material to the polymerisation sites by diffusion through the

aqueous phase. As the micelles grow, they adsorb free emulsifier

from solution, and eventually from the surface of the emulsion

droplets. The emulsifier thus serves to stabilise the polymer particles.

This theory accounts for the observation that the rate of polymerisa-

tion and the number of polymer particles finally produced depend

largely on the emulsifier concentration, and that the number of

polymer particles may far exceed the number of monomer droplets

initially present.

Monodispersed sols containing spherical polymer particles (e.g.

22 24

polystyrene latexes " ' 135 ) can be prepared by emulsion polymer-

isation, and are particularly useful as model systems for studying

various aspects of colloidal behaviour. The seed sol is prepared with

the emulsifier concentration well above the critical micelle concentra-

tion; then, with the emulsifier concentration below the critical micelle

concentration, subsequent growth of the seed particles is achieved

without the formation of further new particles.