Page 122 - Introduction to Marine Engineering

P. 122

Feed systems 109

devaporiser is circulated by the feedwater before it enters the

de-aerator.

The de-aerator feedwater is very close to the steam temperature at the

same pressure and will, if subjected to any pressure drop, 'flash-off into

steam. This can result in 'gassing', i.e. vapour forming in the feed pump

suction. To avoid this problem, the de-aerator is mounted high up in the

machinery space to give a positive suction head to the feed pumps.

Alternatively a booster or extraction pump may be fitted at the

de-aerator outlet.

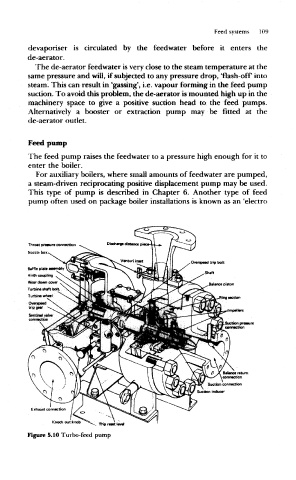

Feed pump

The feed pump raises the feedwater to a pressure high enough for it to

enter the boiler.

For auxiliary boilers, where small amounts of feedwater are pumped,

a steam-driven reciprocating positive displacement pump may be used.

This type of pump is described in Chapter 6. Another type of feed

pump often used on package boiler installations is known as an 'electro

Throat preoura connection

Nozzle box

Baffle plate wwsmbly

Mirth coupling

Wear down cover

Turbine »haft bolt

Turbine wheel

Ovmpeed

trip gear

Suction pmsure

conrwctlon

Exhaust connection

Knock-out knob

Figure 5.10 Turbo-feed pump