Page 222 - Introduction to Marine Engineering

P. 222

Shafting and propellers 203

Where the thrust shaft is an integral part of the engine, the casing is

usually fabricated in a similar manner to the engine bedplate to which it

is bolted. Pressurised lubrication from the engine lubricating oil system

is provided and most other details of construction are similar to the

independent type of thrust block.

Shaft bearings

Shaft bearings are of two types, the aftermost tunnel bearing and all

others. The aftermost tunnel bearing has a top and bottom bearing shell

because it must counteract the propeller mass and take a vertical upward

thrust at the forward end of the tailshaft. The other shaft bearings only

support the shaft weight and thus have only lower half bearing shells.

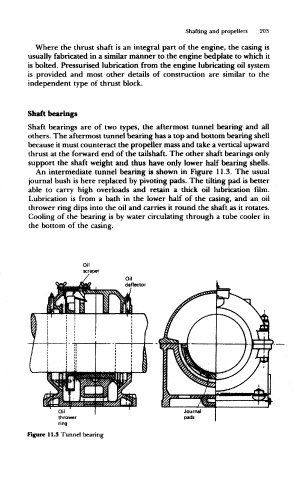

An intermediate tunnel bearing is shown in Figure 11.3. The usual

journal bush is here replaced by pivoting pads. The tilting pad is better

able to carry high overloads and retain a thick oil lubrication film.

Lubrication is from a bath in the lower half of the casing, and an oil

thrower ring dips into the oil and carries it round the shaft as it rotates.

Cooling of the bearing is by water circulating through a tube cooler in

the bottom of the casing.

Figure 11.3 Tunnel bearing