Page 225 - Introduction to Marine Engineering

P. 225

206 Shafting and propellers

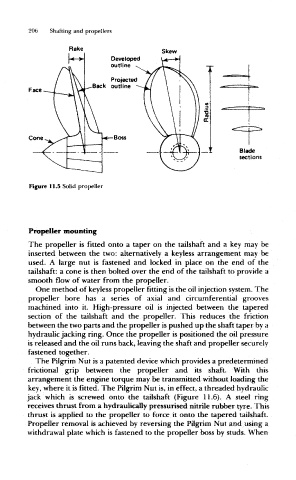

Skew

Developed

outline

Projected

Back outline

Face

Cone Boss

Blade

sections

Figure 11.5 Solid propeller

Propeller mounting

The propeller is fitted onto a taper on the tailshaft and a key may be

inserted between the two: alternatively a keyless arrangement may be

used. A large nut is fastened and locked in place on the end of the

tailshaft: a cone is then bolted over the end of the tailshaft to provide a

smooth flow of water from the propeller.

One method of keyless propeller fitting is the oil injection system. The

propeller bore has a series of axial and circumferential grooves

machined into it. High-pressure oil is injected between the tapered

section of the tailshaft and the propeller. This reduces the friction

between the two parts and the propeller is pushed up the shaft taper by a

hydraulic jacking ring. Once the propeller is positioned the oil pressure

is released and the oil runs back, leaving the shaft and propeller securely

fastened together.

The Pilgrim Nut is a patented device which provides a predetermined

frictional grip between the propeller and its shaft. With this

arrangement the engine torque may be transmitted without loading the

key, where it is fitted. The Pilgrim Nut is, in effect, a threaded hydraulic

jack which is screwed onto the tailshaft (Figure 11.6). A steel ring

receives thrust from a hydraulically pressurised nitrile rubber tyre. This

thrust is applied to the propeller to force it onto the tapered tailshaft.

Propeller removal is achieved by reversing the Pilgrim Nut and using a

withdrawal plate which is fastened to the propeller boss by studs. When