Page 55 - Introduction to Marine Engineering

P. 55

42 Diesel engines

Forward

clutch Output

Forward spider gear

driven Forward Input wheel

gear pinion shaft

Output

shaft

Input

shaft

T

Reverse Output

driven gear Reverse

gear wheel clutch

spider

(a)

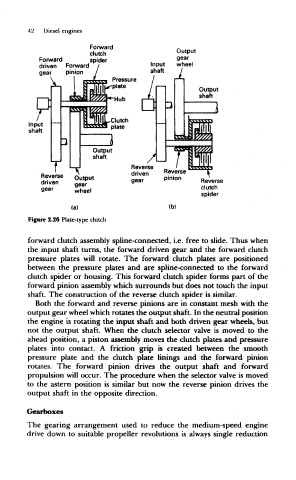

Figure 2.26 Plate-type clutch

forward clutch assembly spline-connected, i.e. free to slide. Thus when

the input shaft turns, the forward driven gear and the forward clutch

pressure plates will rotate. The forward clutch plates are positioned

between the pressure plates and are spline-connected to the forward

clutch spider or housing. This forward clutch spider forms part of the

forward pinion assembly which surrounds but does not touch the input

shaft. The construction of the reverse clutch spider is similar.

Both the forward and reverse pinions are in constant mesh with the

output gear wheel which rotates the output shaft. In the neutral position

the engine is rotating the input shaft and both driven gear wheels, but

not the output shaft. When the clutch selector valve is moved to the

ahead position, a piston assembly moves the clutch plates and pressure

plates into contact. A friction grip is created between the smooth

pressure plate and the clutch plate linings and the forward pinion

rotates. The forward pinion drives the output shaft and forward

propulsion will occur. The procedure when the selector valve is moved

to the astern position is similar but now the reverse pinion drives the

output shaft in the opposite direction.

Gearboxes

The gearing arrangement used to reduce the medium-speed engine

drive down to suitable propeller revolutions is always single reduction