Page 76 - Introduction to Marine Engineering

P. 76

Steam turbines and gearing 63

bearings are of the tilting pad type and are spherically seated. The pads

are thus maintained parallel to the collar and equally loaded. Details of

both types can be seen in Figure 3.5.

Lubricating oil enters a turbine bearing through a port on either side.

The entry point for the oil is chamfered to help distribute the oil along

the bearing. No oil ways are provided in turbine bearings and a greater

clearance between bearing and shaft is provided compared with a diesel

engine. The shaft is able to 'float' on a wedge of lubricating oil during

turbine operation. The oil leaves the bearing at the top and returns to

the drain tank.

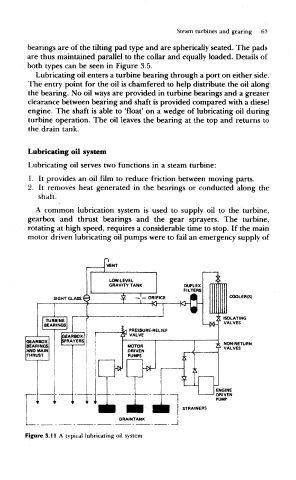

Lubricating oil system

Lubricating oil serves two functions in a steam turbine:

1. It provides an oil film to reduce friction between moving parts.

2. It removes heat generated in the bearings or conducted along the

shaft.

A common lubrication system is used to supply oil to the turbine,

gearbox and thrust bearings and the gear sprayers. The turbine,

rotating at high speed, requires a considerable time to stop. If the main

motor driven lubricating oil pumps were to fail an emergency supply of

COOtER(S)

NON-RETURN

Figure 3,11 A typical lubricating oil system