Page 81 - Introduction to Marine Engineering

P. 81

68 Steam turbines and gearing

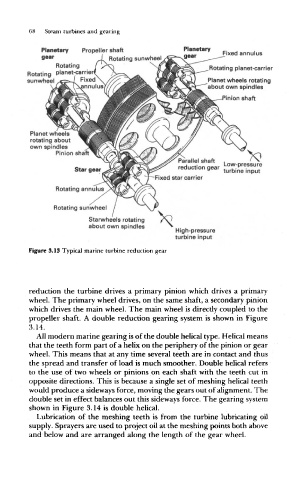

Planetary Propeller shaft Planetary Fixed annulus

§ ear ^ Rotating sunwhee^

Rotating Rotating planet-carrier

Rotating planet-carrier

sun wheel Planet wheels rotating

annul us) about own spindles

Inion shaft

Planet wheels

rotating about

own spindles

Pinion

Parallel shaft .

reduction gear Low-pressure

Star gear a turbine input

^

Rotating annulus

Rotating sunwheel

Starwheels rotating

about own spindles

High-pressure

turbine input

Figure 3.13 Typical marine turbine reduction gear

reduction the turbine drives a primary pinion which drives a primary

wheel. The primary wheel drives, on the same shaft, a secondary pinion

which drives the main wheel. The main wheel is directly coupled to the

propeller shaft. A double reduction gearing system is shown in Figure

3.14.

All modern marine gearing is of the double helical type. Helical means

that the teeth form part of a helix on the periphery of the pinion or gear

wheel. This means that at any time several teeth are in contact and thus

the spread and transfer of load is much smoother. Double helical refers

to the use of two wheels or pinions on each shaft with the teeth cut in

opposite directions. This is because a single set of meshing helical teeth

would produce a sideways force, moving the gears out of alignment. The

double set in effect balances out this sideways force. The gearing system

shown in Figure 3.14 is double helical.

Lubrication of the meshing teeth is from the turbine lubricating oil

supply. Sprayers are used to project oil at the meshing points both above

and below and are arranged along the length of the gear wheel.