Page 83 - Introduction to Marine Engineering

P. 83

70 Steam turbines and gearing

Adaptor

plate

Emergency

Rotor or

^ pinion

flange

Membrane

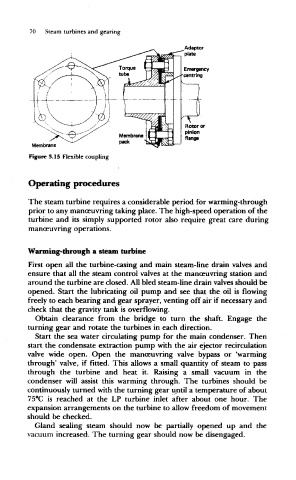

Figure S.I5 Flexible coupling

Operating procedures

The steam turbine requires a considerable period for warming-through

prior to any manoeuvring taking place. The high-speed operation of the

turbine and its simply supported rotor also require great care during

manoeuvring operations.

Warming-through a steam turbine

First open all the turbine-casing and main steam-line drain valves and

ensure that all the steam control valves at the manoeuvring station and

around the turbine are closed. All bled steam-line drain valves should be

opened. Start the lubricating oil pump and see that the oil is flowing

freely to each bearing and gear sprayer, venting off air if necessary and

check that the gravity tank is overflowing.

Obtain clearance from the bridge to turn the shaft. Engage the

turning gear and rotate the turbines in each direction.

Start the sea water circulating pump for the main condenser. Then

start the condensate extraction pump with the air ejector recirculation

valve wide open. Open the manoeuvring valve bypass or 'warming

through' valve, if fitted. This allows a small quantity of steam to pass

through the turbine and heat it. Raising a small vacuum in the

condenser will assist this warming through. The turbines should be

continuously turned with the turning gear until a temperature of about

75°C is reached at the LP turbine inlet after about one hour. The

expansion arrangements on the turbine to allow freedom of movement

should be checked.

Gland sealing steam should now be partially opened up and the

vacuum increased. The turning gear should now be disengaged.