Page 154 - Introduction to Petroleum Engineering

P. 154

ROTARY DRILLING RIGS 141

Crown block

Derrick

or

mast

“Fast line”

of hoisting Traveling block

cable Swivel

“Dead line”

of hoisting

cable

Draw works

Dead line anchor

Rotary table with

kelly bushing

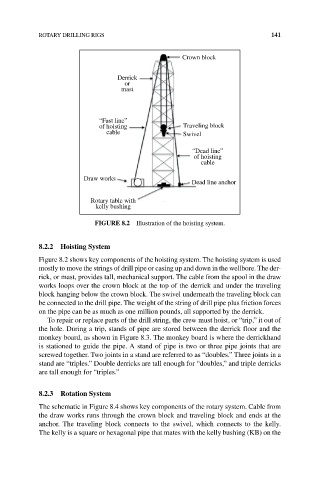

FIGuRe 8.2 Illustration of the hoisting system.

8.2.2 Hoisting System

Figure 8.2 shows key components of the hoisting system. The hoisting system is used

mostly to move the strings of drill pipe or casing up and down in the wellbore. The der-

rick, or mast, provides tall, mechanical support. The cable from the spool in the draw

works loops over the crown block at the top of the derrick and under the traveling

block hanging below the crown block. The swivel underneath the traveling block can

be connected to the drill pipe. The weight of the string of drill pipe plus friction forces

on the pipe can be as much as one million pounds, all supported by the derrick.

To repair or replace parts of the drill string, the crew must hoist, or “trip,” it out of

the hole. During a trip, stands of pipe are stored between the derrick floor and the

monkey board, as shown in Figure 8.3. The monkey board is where the derrickhand

is stationed to guide the pipe. A stand of pipe is two or three pipe joints that are

screwed together. Two joints in a stand are referred to as “doubles.” Three joints in a

stand are “triples.” Double derricks are tall enough for “doubles,” and triple derricks

are tall enough for “triples.”

8.2.3 Rotation System

The schematic in Figure 8.4 shows key components of the rotary system. Cable from

the draw works runs through the crown block and traveling block and ends at the

anchor. The traveling block connects to the swivel, which connects to the kelly.

The kelly is a square or hexagonal pipe that mates with the kelly bushing (KB) on the