Page 152 - Introduction to Petroleum Engineering

P. 152

ROTARY DRILLING RIGS 139

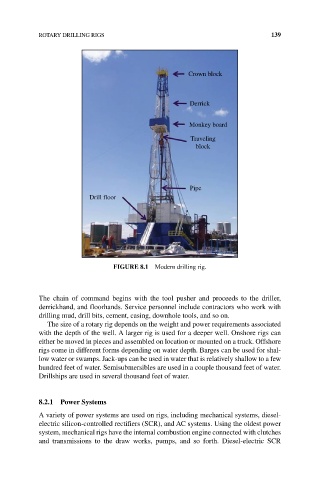

Crown block

Derrick

Monkey board

Traveling

block

Pipe

Drill floor

FIGuRe 8.1 Modern drilling rig.

The chain of command begins with the tool pusher and proceeds to the driller,

derrickhand, and floorhands. Service personnel include contractors who work with

drilling mud, drill bits, cement, casing, downhole tools, and so on.

The size of a rotary rig depends on the weight and power requirements associated

with the depth of the well. A larger rig is used for a deeper well. Onshore rigs can

either be moved in pieces and assembled on location or mounted on a truck. Offshore

rigs come in different forms depending on water depth. Barges can be used for shal-

low water or swamps. Jack‐ups can be used in water that is relatively shallow to a few

hundred feet of water. Semisubmersibles are used in a couple thousand feet of water.

Drillships are used in several thousand feet of water.

8.2.1 Power Systems

A variety of power systems are used on rigs, including mechanical systems, diesel‐

electric silicon‐controlled rectifiers (SCR), and AC systems. Using the oldest power

system, mechanical rigs have the internal combustion engine connected with clutches

and transmissions to the draw works, pumps, and so forth. Diesel‐electric SCR