Page 160 - Introduction to Petroleum Engineering

P. 160

ROTARY DRILLING RIGS 147

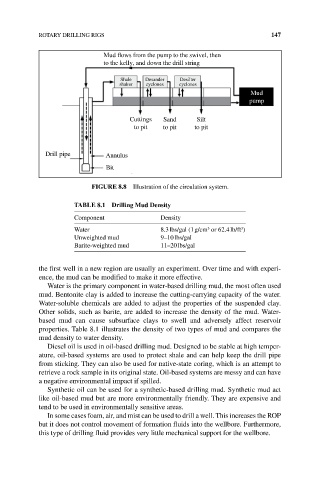

Mud ows from the pump to the swivel, then

to the kelly, and down the drill string

Shale Desander Desilter

shaker cyclones cyclones

Mud

pump

Cuttings Sand Silt

to pit to pit to pit

Drill pipe Annulus

Bit

FIGuRe 8.8 Illustration of the circulation system.

TABLe 8.1 Drilling Mud Density

Component Density

Water 8.3 lbs/gal (1 g/cm or 62.4 lb/ft )

3

3

Unweighted mud 9–10 lbs/gal

Barite‐weighted mud 11–20 lbs/gal

the first well in a new region are usually an experiment. Over time and with experi-

ence, the mud can be modified to make it more effective.

Water is the primary component in water‐based drilling mud, the most often used

mud. Bentonite clay is added to increase the cutting‐carrying capacity of the water.

Water‐soluble chemicals are added to adjust the properties of the suspended clay.

Other solids, such as barite, are added to increase the density of the mud. Water‐

based mud can cause subsurface clays to swell and adversely affect reservoir

properties. Table 8.1 illustrates the density of two types of mud and compares the

mud density to water density.

Diesel oil is used in oil‐based drilling mud. Designed to be stable at high temper-

ature, oil‐based systems are used to protect shale and can help keep the drill pipe

from sticking. They can also be used for native‐state coring, which is an attempt to

retrieve a rock sample in its original state. Oil‐based systems are messy and can have

a negative environmental impact if spilled.

Synthetic oil can be used for a synthetic‐based drilling mud. Synthetic mud act

like oil‐based mud but are more environmentally friendly. They are expensive and

tend to be used in environmentally sensitive areas.

In some cases foam, air, and mist can be used to drill a well. This increases the ROP

but it does not control movement of formation fluids into the wellbore. Furthermore,

this type of drilling fluid provides very little mechanical support for the wellbore.