Page 192 - Know and Understand Centrifugal Pumps

P. 192

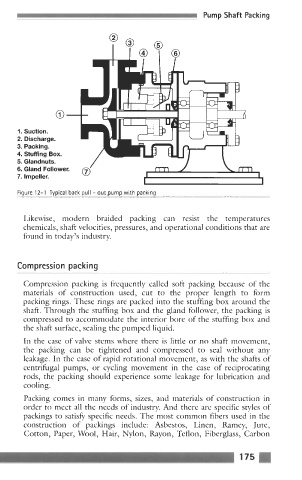

Pump Shaft Packing

0

1. Suction.

2. Discharge.

3. Packing.

4. Stuffing Box.

5. Glandnuts.

6. Gland Follower.

7. Impeller.

Figure 12-1 Typical back pull - out pump with packing

Likewise, modern braided packing can resist the temperatures

chemicals, shaft velocities, pressures, and operational conditions that are

found in today’s industry.

Corn pressi on pac ki ng

Compression packing is frequently called soft packing because of the

materials of construction used, cut to the proper length to form

packing rings. These rings are packed into the stuffing box around the

shaft. Through the stuffing box and the gland follower, the packing is

compressed to accommodate the interior bore of the stuffing box and

the shaft surface, sealing the pumped liquid.

In the case of valve stems where there is little or no shaft movement,

the packing can be tightened and compressed to seal without any

leakage. In the case of rapid rotational movement, as with the shafts of

centrifugal pumps, or cycling movement in the case of reciprocating

rods, the packing should experience some leakage for lubrication and

cooling.

Packing comes in many forms, sizes, and materials of construction in

order to meet all the needs of industry. And there are specific styles of

packings to satisfy specific needs. The most common fibers used in the

construction of packings include: Asbestos, Linen, Ramey, Jute,

Cotton, Paper, Wool, Hair, Nylon, Rayon, Teflon, Fiberglass, Carbon

175