Page 209 - Know and Understand Centrifugal Pumps

P. 209

Know and Understand Centrifugal Pumps

50% 50% of face contact

area sees closing

50% force.

Figure 13-14

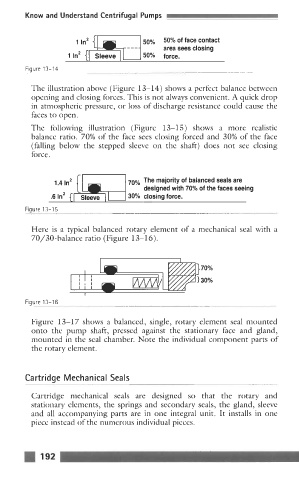

The illustration above (Figure 13-14) shows a perfect balance between

opening and closing forces. This is not always convenient. A quick drop

in atmospheric pressure, or loss of discharge resistance could cause the

faces to open.

The following illustration (Figure 13-1 5) shows a more realistic

balance ratio. 70% of the face sees closing forced and 30% of the face

(falling below the stepped sleeve on the shaft) does not see closing

force.

1.4 In2 70% The majority of balanced seals are

designed with 70% of the faces seeing

.61n2 {I Sleeve I 30% closing force.

Figure 13-15

Here is a typical balanced rotary element of a mechanical seal with a

70/30-balance ratio (Figure 13-16).

] 70%

3 30%

Fiaure 13-16

Figure 13-17 shows a balanced, single, rotary element seal mounted

onto the pump shaft, pressed against the stationary face and gland,

mounted in the seal chamber. Note the individual component parts of

the rotary element.

Ca rt r i dg e M ec h a n ica I Sea Is

Cartridge mechanical seals are designed so that the rotary and

stationary elements, the springs and secondary seals, the gland, sleeve

and all accompanying parts are in one integral unit. It installs in one

piece instead of the numerous individual pieces.

192