Page 227 - Know and Understand Centrifugal Pumps

P. 227

Know and Understand Centrifugal Pumps

The pump shaft must be free to slide through the O-ring. However,

crystallizing liquids, accumulated solids and pastes, and products that

harden can cause the O-ring to hang-up or stick to the shaft losing its

freedom. Oversized shafts and sleeves can also be blamed. If the seal is

misaligned onto the shaft the O-ring can fret the shaft and hang into its

groove. Heat and chemical attack can also make the O-ring vulcanize to

the shaft. Any of these can occur. As the shaft moves within the

tolerance of the bearings, it can drag the seal faces open or crush them

together if the O-ring sticks to the shaft.

The springs clog and jam

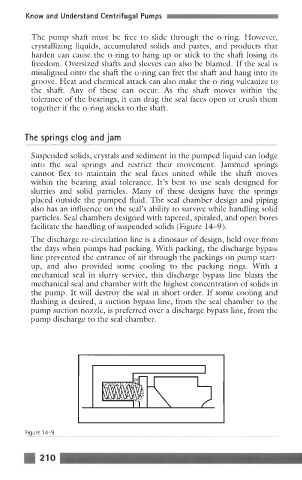

Suspended solids, crystals and sediment in the pumped liquid can lodge

into the seal springs and restrict their movement. Jammed springs

cannot flex to maintain the seal faces united while the shaft moves

within the bearing axial tolerance. It’s best to use seals designed for

slurries and solid particles. Many of these designs have the springs

placed outside the pumped fluid. The seal chamber design and piping

also has an influence on the seal’s ability to survive while handling solid

particles. Seal chambers designed with tapered, spiraled, and open bores

facilitate the handling of suspended solids (Figure 14-9).

The discharge re-circulation line is a dinosaur of design, held over from

the days when pumps had packing. With packing, the discharge bypass

line prevented the entrance of air through the packings on pump start-

up, and also provided some cooling to the packing rings. With a

mechanical seal in slurry service, this discharge bypass line blasts the

mechanical seal and chamber with the highest concentration of solids in

the pump. It will destroy the seal in short order. If some cooling and

flushing is desired, a suction bypass line, from the seal chamber to the

pump suction nozzle, is preferred over a discharge bypass line, from the

pump discharge to the seal chamber.

II 1

I I I

Fiaure 14-9

210