Page 229 - Know and Understand Centrifugal Pumps

P. 229

Know and Understand Centrifugal Pumps

The O-ring seal gripping the shaft moves

1,800 rpm x 2 movements/revolution = 3,600 movements/

minute.

3,600 movements/min x 60 minutes/hour = 216,000

movements/hour

216,000 movements/hour x 24 hours/day = 5,184,000

movements per day

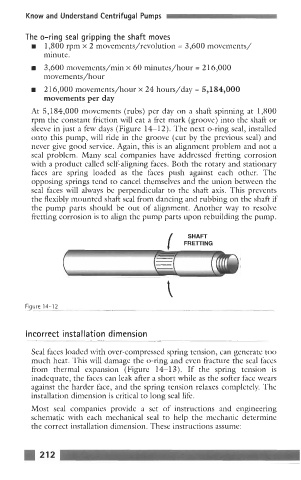

At 5,184,000 movements (rubs) per day on a shaft spinning at 1,800

rpm the constant friction will eat a fret mark (groove) into the shaft or

sleeve in just a few days (Figure 14-12). The next O-ring seal, installed

onto this pump, will ride in the groove (cut by the previous seal) and

never give good service. Again, this is an alignment problem and not a

seal problem. Many seal companies have addressed fretting corrosion

with a product called self-aligning faces. Both the rotary and stationary

faces are spring loaded as the faces push against each other. The

opposing springs tend to cancel themselves and the union between the

seal faces will always be perpendicular to the shaft axis. This prevents

the flexibly mounted shaft seal from dancing and rubbing on the shaft if

the pump parts should be out of alignment. Another way to resolve

fretting corrosion is to align the pump parts upon rebuilding the pump.

SHAFT

[ FRElTlNG

I I -- I

t

Figure 14-12 __

Incorrect installation dimension

Seal faces loaded with over-compressed spring tension, can generate too

much heat. This will damage the O-ring and even fiacture the seal faces

from thermal expansion (Figure 14-13). If the spring tension is

inadequate, the faces can leak after a short while as the softer face wears

against the harder face, and the spring tension relaxes completely. The

installation dimension is critical to long seal life.

Most seal companies provide a set of instructions and engineering

schematic with each mechanical seal to help the mechanic determine

the correct installation dimension. These instructions assume: